How to break in your power hammer

Tips for Breaking-in Power Hammer

Dear ANYANG ST Hammer buyers:

Congratulations to you get a Brand new Anyang ST Power hammer. To keep you power hammer has a better performance in the following days, Some tips must be fulfilled during the breaking-in period.

1. Grease the moderate lubricating oil with the correct grade

1.1 Choose the suitable lubricating oil

5W-40 or 5W-30 lubricating oil is recommended, 5W-20 or 5W-10 lubrication oil is recommend when the temperature below -10 degrees, to ensure the oil has good fluidity when the hammer is working. Since the hammer working temperature is about 70 degrees, the frequency is 200-300 times, which is much lower compared with the requirements for lubricating oil of automobile engines.

1.2 Lubricating oil volume

Please add the lubricating oil volume between the two oil gauges as shown in the figure below, And please pay attention to the volume of lubricating oil and replenish it in time.

- Suitable Lubricating oil supply

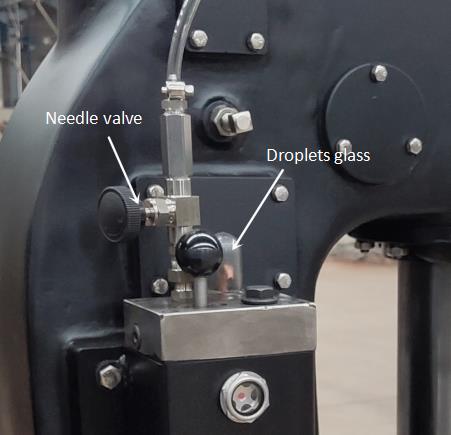

Breaking-in period is defined as 8-10 hours. The oil supply can be accurately controlled by adjusting the needle valve on the pipeline, and the oil droplets glass cover above the oil pump can be observed to determine the oil supply. During the breaking-in period, the oil volume should be adjusted to 2-3 seconds per drop to ensure the oil film or even black oil dripping can be clearly seen on the hammer ram. This is a normal phenomenon of the internal cleaning of the new machine. After the breaking-in period, it is recommended to adjust the amount of oil to 7-8 seconds per drop (oil with different viscosity can be adjusted appropriately).

- Breaking-in period operation

First, ensure that the electrical connection is reliable, the pointer is at the hammer lifting position during working, plug in, adjust the needle valve, and keep hammer run unloading for 3-5 minutes to observe whether the lubricant can be sucked into the machine.

Then, lightly step on the pedal to move the hammer rod up and down so that the lubricating oil would blown into the front cylinder by the air. During the breaking-in period, will not recommend to do heavy forging work. better to forging some small and exquisite work-piece, just keep the hammer on working. And pay attention to the oil volume in the oiler to ensure it is in a reasonable range.