Overview of the pneumatic power hammer in China

brief overview of the pneumatic power hammer in China

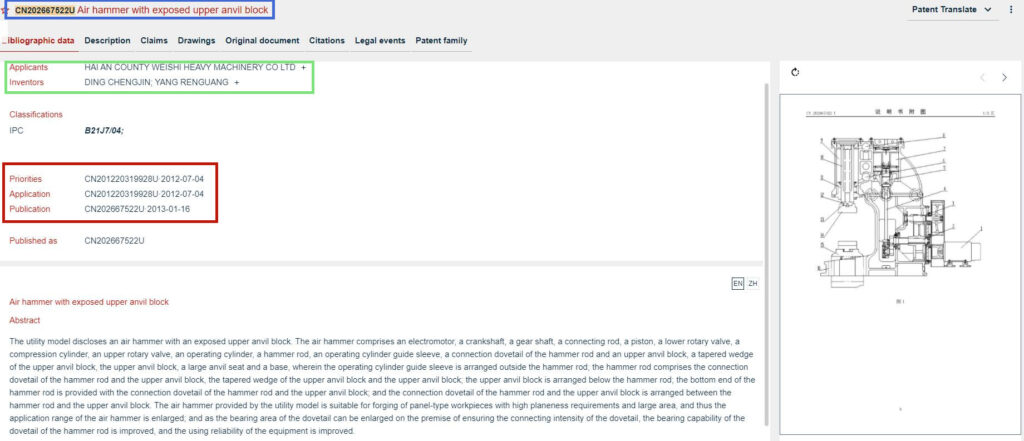

The following is a brief overview of the pneumatic power hammer in China. The Chinese traditional pneumatic hammer (china power hammer) technology was imported from the former Soviet Union in the 1950s. A design flaw of these early hammers was the length of the ram. During the normal operating cycle of the power hammer, the key and top die or anvil attached to the ram would retract into the cylinder, during the top of the stroke. Damage could occur to the pneumatic forging hammers guide sleeve of the working cylinder and ram if the key holding the upper anvil in a secure position became loose during the hammer operation.

Why make the long ram design

The solution was to lengthen the short ram. This new design eliminated the key and die retracting into the cylinder bore. With the cylinder no longer a limiting factor this allowed the use of larger working dies to be used on the hammer. An additional added benefit for the power hammers. The working performance of this new design improvement has proven to be reliable over the past several years of production and use in the industry. The new longer ram design was designed by Hai An County Weishi heavy machinery located in Nantong, China on 04/07/2012. This was a major improvement.

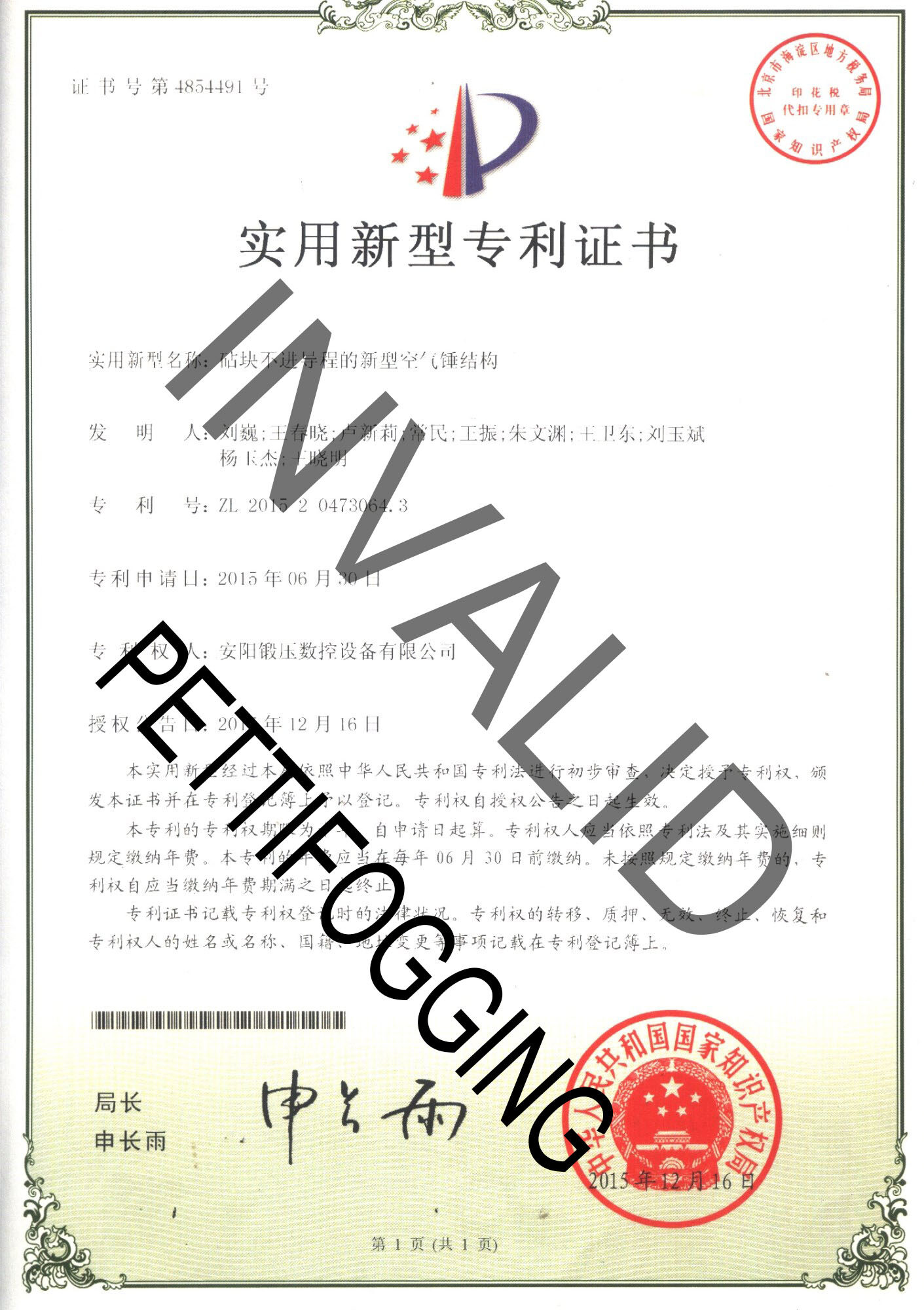

State Intellectual Property Office of P.R.China rejected AFP tried apply this design as theirs.

AFP tried to apply this design as theirs on 12/16/2015 but was rejected by the State Intellectual Property Office of P.R.China. This design improvement has now been open since 08/17/2016 for the use of all.

anyang power hammer

In recent years, other power hammers factories have started to use this same or similar design in their production of products. The power hammer is one of the general forging machines in the metal shaping industry and has been for over 100 years. This very design has been known and used by many others including production from other manufacturers.

learn more…